Contact us

WS.PEMS for

Boilers & Heaters

PEMS for Boilers & Heaters: Obtain accurate emissions data and achieve compliance with international regulations

The boiler and heater models WS.PEMS is using an extensive set of physical relations governing the operation of the equipment. This includes energy and mass balances as well as equipment characteristics. The First Principle Model makes maximum use of the instrumentation available in the control system.

What you receive

PEMS for Boilers & Heaters: Obtain accurate emissions data and achieve compliance with international regulations

First Principle Model

Compliance

The Path Forward

Selected references for boilers & heaters

| Customer | Year | Project |

|---|---|---|

| Aramco | 2012 | Tanajib, Safanya, KSA |

| Aramco | 2018 | Qatif, Juaymah, KSA |

Discover More

Download our PDF to learn more about WS.PEMS, or explore additional information on our website.

Download WS.PEMS PDF

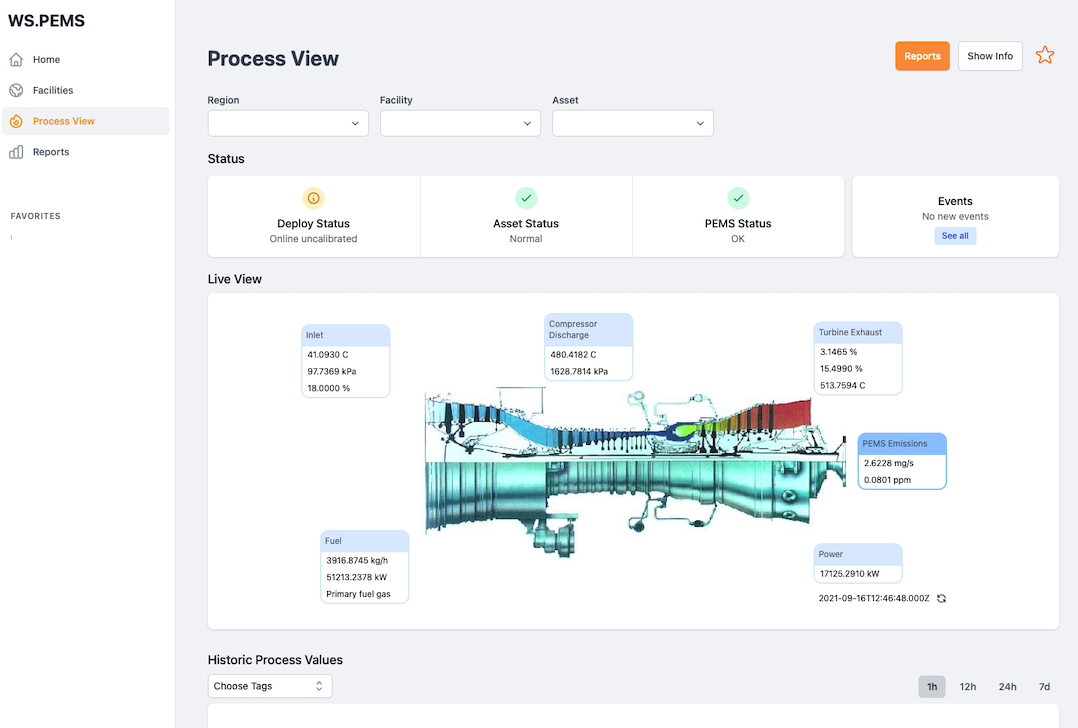

Gain insights into WS.PEMS and its benefits of using predictive emission monitoring systems for gas turbines.

Read More About WS.PEMS

Explore further details about WS.PEMS our predictive emission monitoring system.